Zirconia Ceramic Balls have emerged as a revolutionary solution in precision applications, offering remarkable enhancements in durability and performance. As reported by a recent market analysis from Smithers Pira, the global ceramics market is projected to reach $2.4 billion by 2025, with zirconia-based products gaining substantial market share due to their superior mechanical properties. These high-performance balls demonstrate exceptional resistance to wear, corrosion, and thermal stress, making them ideal for demanding environments where reliability is critical. Moreover, their low density and high hardness provide significant advantages in various applications, including automotive, aerospace, and medical devices. The versatility and efficiency of Zirconia Ceramic Balls position them as a key component in advancing technology and enhancing performance across multiple industries.

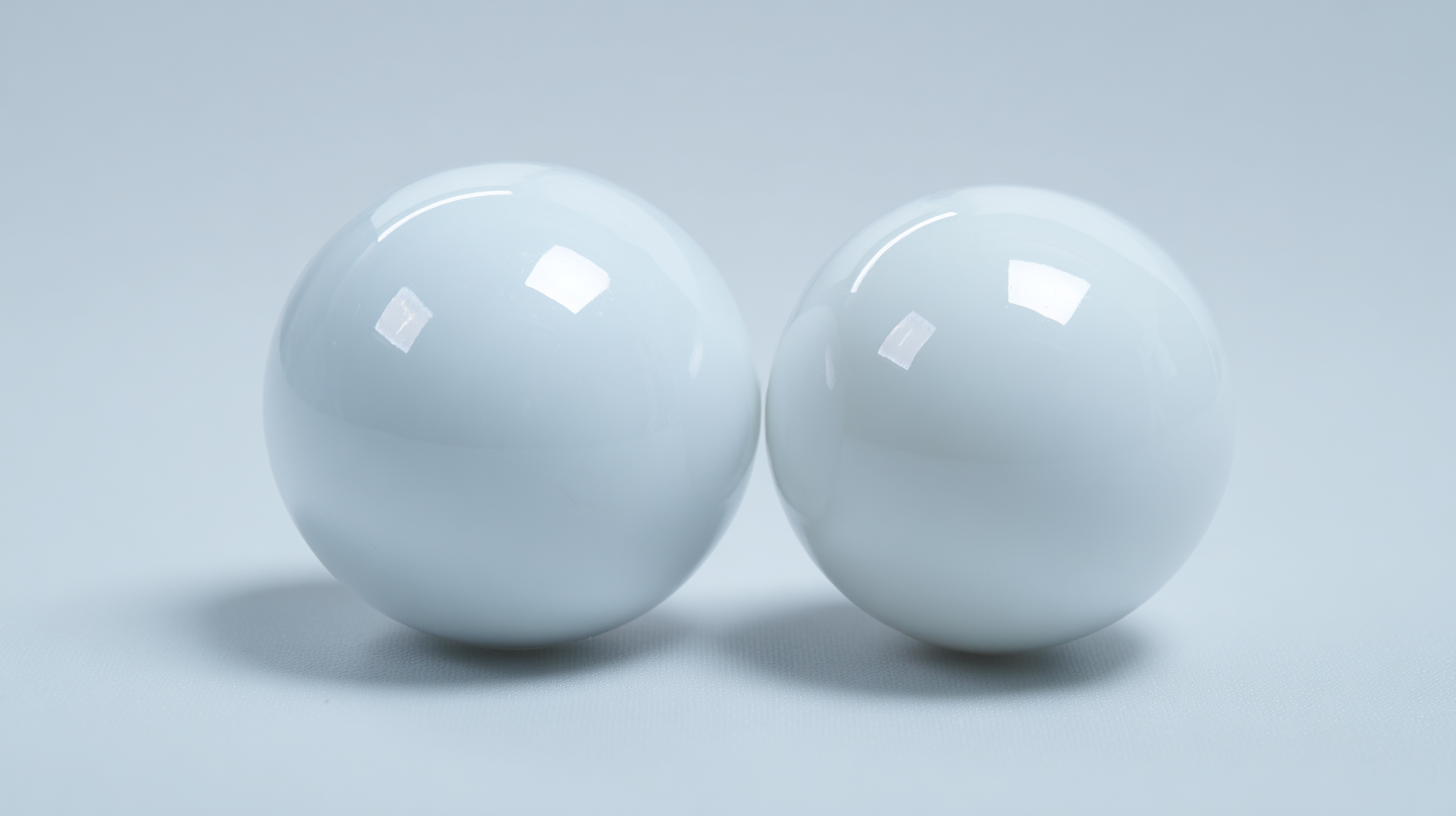

Zirconia ceramic balls have become increasingly significant in precision engineering due to their unique composition and superior properties. Composed primarily of zirconium dioxide (ZrO2), these ceramic balls exhibit exceptional strength and toughness, making them ideal for applications that demand high durability. The addition of stabilizers, such as yttria, enhances their mechanical properties, allowing them to withstand extreme conditions, including high temperatures and abrasive environments. This stability greatly reduces the wear and tear often seen in traditional materials, contributing to longer operational lifespans of machinery and components.

Moreover, the inherent chemical stability of zirconia ceramic balls allows them to resist corrosion and oxidation, further solidifying their role in precision applications. Their low friction coefficients and superior surface finish minimize energy loss and improve overall performance in systems such as bearings, valves, and pumps. By integrating zirconia ceramic balls into engineering designs, industries can achieve significant enhancements in efficiency, reliability, and cost-effectiveness. This understanding of their composition and benefits showcases why zirconia ceramic balls are favored in high-performance contexts where precision and longevity are paramount.

Zirconia ceramic balls have emerged as an exceptional alternative to traditional materials in high-stress applications, primarily due to their remarkable mechanical properties. One of the key advantages of zirconia balls is their superior hardness, which translates to enhanced wear resistance. This characteristic enables them to withstand the rigors of heavy loads and abrasive environments, making them ideal for use in precision machinery, automotive components, and aerospace applications.

Moreover, zirconia ceramic balls exhibit outstanding thermal stability, allowing them to maintain their performance under extreme temperature variations. Unlike conventional materials, which may suffer from thermal expansion and deformation, zirconia balls retain their dimensional integrity, thereby ensuring consistent functionality. Additionally, their low friction coefficient significantly contributes to reduced energy loss and prolonged service life, positioning them as a highly efficient solution in precision engineering sectors.

This combination of durability and performance not only optimizes operational efficiency but also lowers maintenance costs, solidifying zirconia's place as a preferred choice in modern applications.

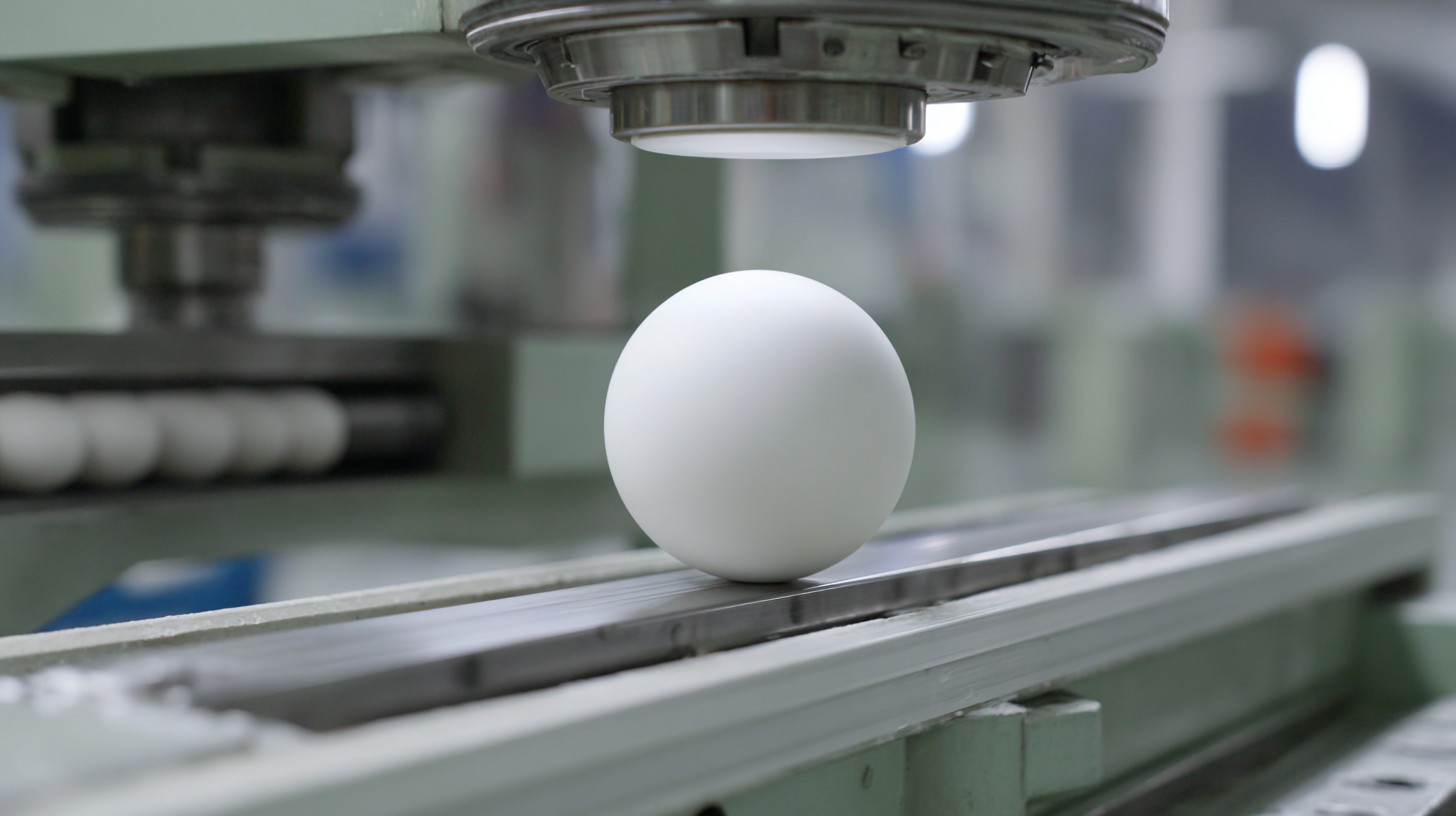

Zirconia ceramic balls have emerged as a critical component in various precision applications due to their remarkable wear resistance and longevity. The unique properties of zirconia, such as its high mechanical strength and toughness, allow these balls to withstand extreme conditions that would typically degrade other materials. In specialized environments, such as those found in aerospace and medical devices, the durability of zirconia ceramic balls ensures reliable performance, reducing the frequency of replacements and minimizing downtime.

Performance metrics for evaluating the wear resistance of zirconia ceramic balls include standardized tests that measure abrasion, hardness, and fatigue under operational stress. These tests consistently show that zirconia outperforms traditional materials like steel and plastic, particularly in applications that involve high temperatures or corrosive substances. The extended lifespan of zirconia ceramic balls not only enhances operational efficiency but also contributes to cost savings for manufacturers, making them an ideal choice for precision engineering demands.

Zirconia ceramic balls have gained significant traction across various industries due to their exceptional performance characteristics. In the automotive sector, these balls are used in high-performance bearings, where their low friction and high wear resistance enhance the lifespan and efficiency of engines. Case studies reveal that implementing zirconia ceramic balls can lead to a 30% reduction in maintenance costs, demonstrating their cost-effectiveness in precision applications.

Another prominent application is found in the medical industry, where zirconia ceramic balls are utilized in dental implants and prosthetics. Their biocompatibility and durability ensure a longer service life, reducing the need for frequent replacements. Performance data indicates that implants with zirconia components show a 25% higher success rate over a five-year period compared to traditional materials. Such data underscores the importance of zirconia ceramic balls in advancing both the performance and reliability of products in demanding environments.

| Industry | Application | Performance Improvement | Durability Rating | Cost Efficiency |

|---|---|---|---|---|

| Aerospace | High-speed bearings | Reduced friction | 9/10 | Lower maintenance costs |

| Medical Devices | Dental implants | Enhanced biocompatibility | 10/10 | Longer device life |

| Automotive | Fuel pumps | Increased efficiency | 8/10 | Optimized fuel consumption |

| Electronics | High-frequency oscillators | Improved signal stability | 9/10 | Reduced power loss |

| Manufacturing | Grinding mills | Higher throughput | 9/10 | Lower energy costs |

Investing in zirconia ceramic balls presents a compelling case for industries seeking enhanced performance and longevity in their precision applications. These advanced materials offer remarkable durability, which translates into reduced wear and tear over time. The initial costs of zirconia ceramic balls can be higher than traditional materials, but when viewed through a long-term lens, the economic benefits become evident. The reduced frequency of replacements and lower maintenance costs contribute significantly to overall savings.

Moreover, the efficiency gained from using zirconia ceramic balls in high-speed operations cannot be overlooked. Their superior hardness and resistance to corrosion ensure that machinery runs smoother and longer, minimizing downtime. This increased operational uptime allows businesses to enhance productivity and meet demands more effectively. In essence, while the upfront investment might seem substantial, the cost-benefit analysis favors zirconia ceramic balls as a strategic investment that supports long-term durability and operational efficiency, making them an attractive choice for precision engineering applications.