Zirconia Beads for Grinding Media have gained significant recognition in various industries for their superior performance and efficiency in the grinding process. As industries strive for higher product quality and reduced processing times, the demand for advanced grinding media has surged. According to a recent market analysis, the global market for grinding media is anticipated to reach $7.5 billion by 2026, with zirconia beads accounting for a considerable share due to their unique properties such as high density, toughness, and chemical inertness.

The utilization of Zirconia Beads for Grinding Media not only enhances the grinding efficiency but also leads to lower contamination levels in the end products. This is particularly crucial in sectors like pharmaceuticals and paints, where purity is paramount. Industry reports indicate that the use of zirconia beads can increase the grinding efficiency by up to 50%, contributing to reduced operational costs and improved output quality. Furthermore, their durability allows for longer service life compared to traditional media, leading to less frequent replacements and decreased downtime in production processes. As such, zirconia beads represent not just an improvement in grinding technology, but a strategic investment in bolstering overall operational performance within various manufacturing sectors.

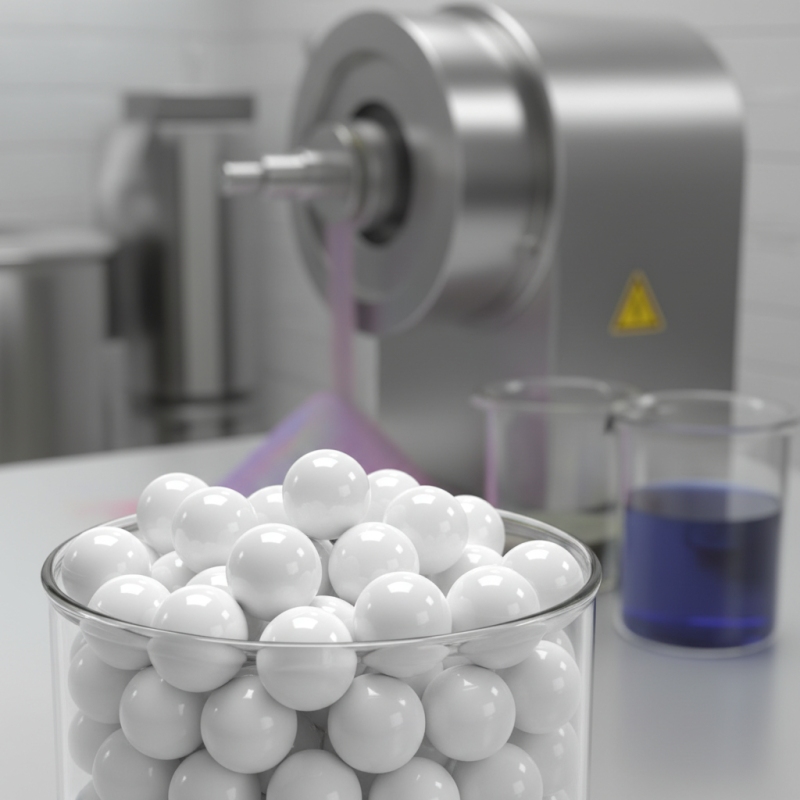

Zirconia beads, known for their exceptional hardness and durability, are increasingly used as a grinding medium in various milling applications. These beads are primarily composed of zirconium dioxide (ZrO2), which contributes to their high density and resistance to wear. This composition ensures that they can withstand intense mechanical stresses without fracturing, making them ideal for grinding materials that require both precision and efficiency.

In addition to their robust composition, zirconia beads are characterized by their low porosity and smooth surface finish. These properties lead to minimal contamination during the grinding process, which is particularly important in applications such as paint, ink, and pharmaceutical manufacturing. The uniform size and shape of these beads allow for optimal grinding performance, enabling finer particle sizes and enhanced dispersion of materials. Consequently, zirconia beads have become a preferred choice for industries seeking to improve the quality of their products while reducing the time and energy spent on milling processes.

| Property | Details |

|---|---|

| Material Composition | Zirconium Dioxide (ZrO2) with stabilizers such as Yttrium Oxide (Y2O3) |

| Density | Approximately 6.0 g/cm³ |

| Hardness | Very hard, approximately 1200-1400 HV |

| Application Areas | Paints, inks, ceramics, electronics, and pharmaceuticals |

| Advantages | High wear resistance, chemical stability, and excellent grinding efficiency |

| Size Range | From 0.5 mm to 5 mm |

| Color | White or off-white |

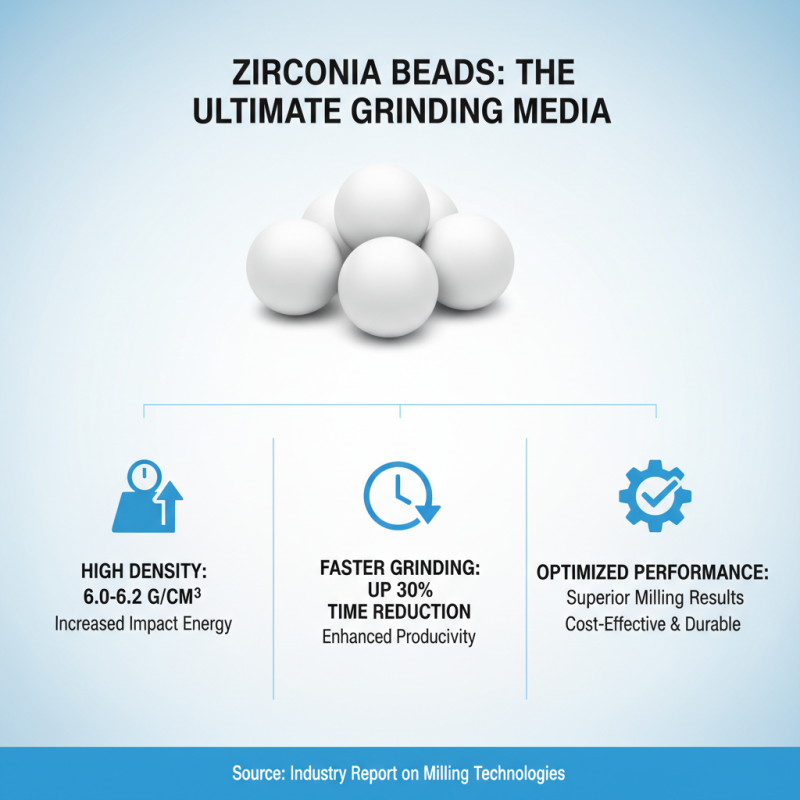

Zirconia beads have emerged as a highly efficient grinding media due to their exceptional properties that enhance grinding performance. One of the key characteristics of zirconia beads is their high density, typically around 6.0 to 6.2 g/cm³. This high density contributes to improved impact energy, enabling faster grinding and increased productivity in milling processes. According to a recent industry report, the use of zirconia beads can lead to a reduction in processing time by up to 30% compared to traditional grinding media, making them an attractive option for manufacturers looking to optimize their operations.

Another notable feature of zirconia beads is their excellent wear resistance. Their hardness, rated at about 1200 Vickers, ensures minimal wear during grinding, which translates into lower contamination of the final product and increased lifespan of both the beads and the milling equipment. This property is crucial, especially in industries such as pharmaceuticals and ceramics, where purity and minimal contamination are paramount. Studies show that the use of zirconia beads can reduce the wear rate by up to 50% compared to alternative materials, thus providing long-term cost benefits and enhancing overall grinding efficiency.

The spherical shape of zirconia beads also contributes to their effectiveness in grinding applications. This geometry ensures uniform particle size distribution and effective dispersion, leading to more consistent processing results. Recent advancements in manufacturing techniques have allowed for the production of zirconia beads with highly controlled sizes ranging from 0.1 mm to 2.0 mm, catering to various applications in the industry. Coupled with their high resistivity to chemical corrosion, zirconia beads offer an all-around solution for achieving superior grinding efficiency in diverse processes.

Zirconia beads have gained widespread acceptance as grinding media in various industries due to their excellent properties, such as high density, low wear rate, and resistance to chemicals. In the field of ceramics, for instance, these beads are pivotal in enhancing the grinding process, enabling finer particle sizes and improving the overall quality of the final product. According to recent industry reports, the global market for zirconia beads is expected to reach approximately $1 billion by 2025, underscoring the growing demand across multiple sectors.

In the paint and coatings industry, zirconia beads are utilized for their superior grinding efficiency, which leads to smoother finishes and better dispersion of pigments. Their round shape and exceptional hardness make them ideal for high-energy milling processes. Reports indicate that the use of zirconia beads can increase the dispersion quality by up to 30%, significantly impacting the performance attributes of paints and coatings. Additionally, these beads find applications in the production of pharmaceuticals, where their non-reactive nature is essential for maintaining purity and safety in drug formulations. The enhanced grinding results in improved bioavailability, thereby optimizing therapeutic efficacy.

Zirconia beads have emerged as a superior choice in the realm of grinding media, particularly when compared to other materials like glass, steel, and alumina. One of the key advantages of zirconia beads is their exceptional durability, characterized by high resistance to wear and breakage. According to a report by the International Journal of Advanced Manufacturing Technology, zirconia beads can last up to 10 times longer than steel beads in certain applications, translating to fewer replacements and reduced operational costs. Additionally, their density contributes to more effective grinding, which is crucial in industries like ceramics, coatings, and inks.

When juxtaposed with glass and alumina, zirconia beads also exhibit superior grinding efficiency. Glass beads may shatter under stress and produce undesirable contaminants, rendering them less effective for high-purity applications. Alumina beads, while commonly used, can wear down quickly, leading to increased downtime for maintenance. The hardness of zirconia, rated around 1200 HV, provides a competitive edge, allowing them to deliver better particle size distribution and finer grinding results.

Tips: Always consider the specific requirements of your grinding process before selecting media. Conduct small-scale tests to evaluate the performance of zirconia beads against other materials in your specific application to ensure optimal results. Regularly monitor wear patterns and operational efficiency to maximize the benefits of your chosen grinding media.

Zirconia beads have gained significant traction in the field of grinding media due to their unique properties and numerous benefits. One of the primary advantages of using zirconia beads is their ability to significantly reduce contamination during the grinding process. Unlike traditional grinding media, which may release foreign particles into the product, zirconia beads are chemically inert and possess a high density, allowing for efficient grinding with minimal wear. According to a study published by the Journal of Material Science, zirconia beads can decrease contamination levels by up to 80% compared to other materials, making them an excellent choice for industries where purity is paramount, such as pharmaceuticals and food processing.

Furthermore, the cost-effectiveness of zirconia beads cannot be overlooked. While the initial investment may be higher than conventional options, their durability and resistance to wear lead to longer service life and reduced replacement frequency. The Journal of Ceramic Science highlights that manufacturers using zirconia beads report a reduction in operational costs by as much as 30% over time due to lower media consumption and less downtime for maintenance. As industries strive for efficiency and sustainability, the adoption of zirconia beads presents a dual benefit: they not only enhance product quality by minimizing contamination but also offer substantial savings in overall operational costs.