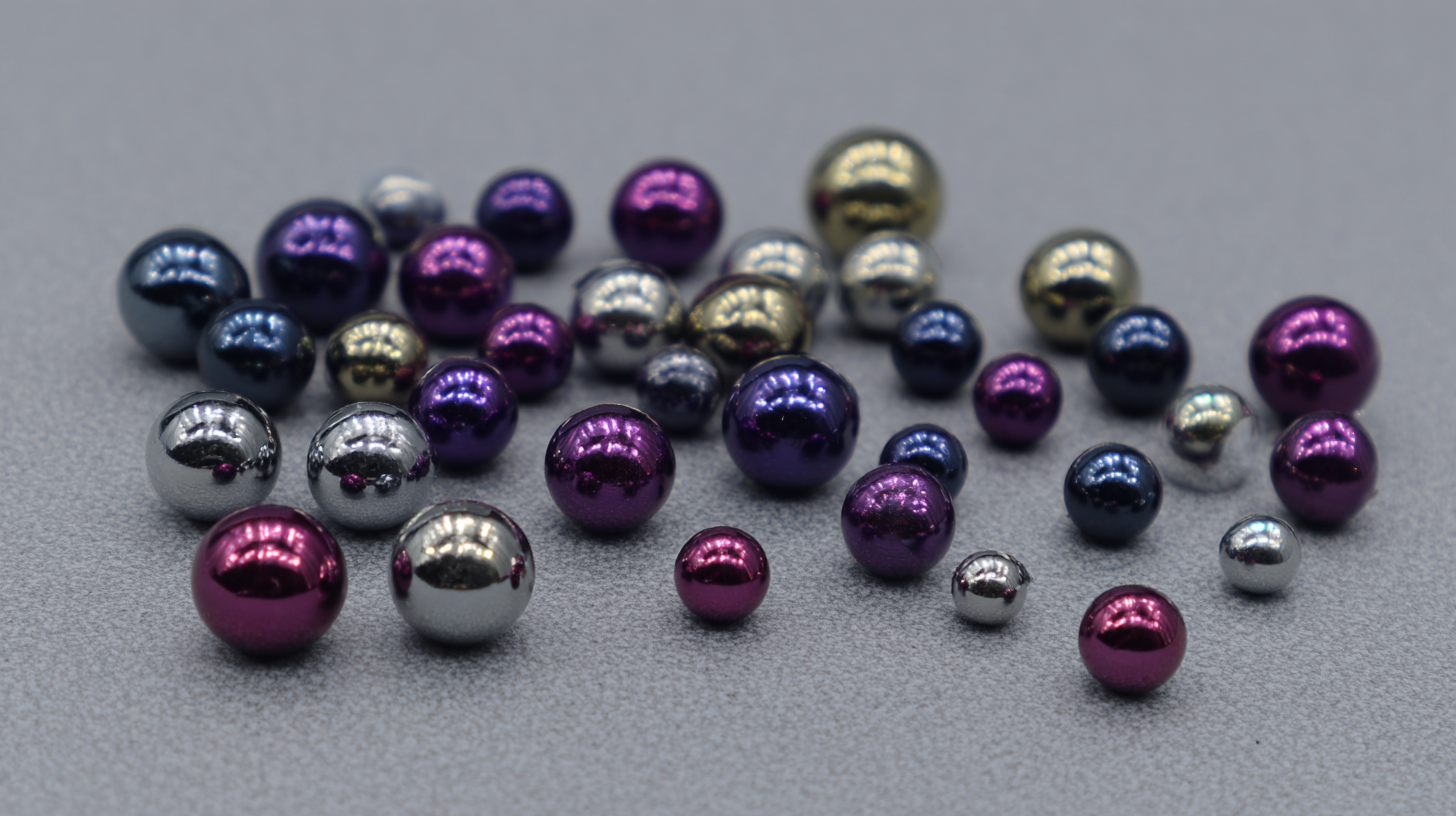

In today's competitive industrial landscape, achieving optimal performance often hinges on the materials we choose for our processes. One such material that has garnered significant attention for its superior properties is 95 Zirconium Beads. Known for their exceptional durability, chemical resistance, and uniform size, these beads serve as a critical component in various applications, from grinding and milling to mixing and dispersing. This blog aims to explore innovative solutions for enhancing performance through the effective use of 95 Zirconium Beads. By understanding their unique characteristics and how they can be integrated into different industrial processes, businesses can unlock new levels of efficiency and productivity. Join us as we delve into practical tips and strategies for maximizing the benefits of 95 Zirconium Beads in your operations, ultimately driving forward the success of your industrial applications.

Zirconium beads are increasingly recognized for their high performance in various industrial applications, particularly in processes requiring precision and durability. The benefits of using high-quality zirconium beads in industrial processes are manifold. They offer excellent wear resistance and low contamination levels, contributing to the purity of the materials being processed. Additionally, their chemical stability ensures that they can withstand aggressive environments, making them ideal for a wide range of applications, including milling and dispersion.

Tip: When selecting zirconium beads for your processes, consider the size and shape that best suits your application. Smaller beads can lead to finer particle sizes, while specific shapes may enhance the efficiency of the milling process.

Moreover, the adoption of zirconium beads in grinding and dispersion not only enhances product quality but also improves overall operational efficiency. This is particularly important in industries such as lithium battery production, where consistent particle size can significantly influence the performance of the final product.

Tip: Regularly monitor the performance of your zirconium beads to ensure optimal grinding action. Replace worn beads promptly to maintain efficiency and product integrity.

The manufacturing of high-quality zirconium beads has become essential in various industrial applications, particularly in abrasive processes and milling operations. Key techniques in the production of superior zirconium beads involve precise control of the raw material composition and rigorous processing methods. For instance, according to a report by Freedonia Group, the global demand for zirconium silicate, a critical precursor for high-performance zirconium beads, is projected to grow by 4.5% annually, emphasizing the need for advanced manufacturing techniques to meet market needs.

One innovative manufacturing technique is the high-energy ball milling process, which significantly enhances the uniformity and density of the zirconium beads. This approach not only improves the mechanical properties of the beads but also optimizes their wear resistance, as highlighted in a study by the Journal of Materials Science. This publication noted that beads produced through advanced techniques have exhibited up to 30% increase in durability compared to conventional counterparts, making them highly desirable for industries that rely heavily on grinding and milling processes. As manufacturers adopt such cutting-edge techniques, the resulting zirconium beads can better withstand harsh working conditions, leading to improved operational efficiency and reduced downtime.

In recent years, zirconium beads have emerged as a preferred choice for various industrial applications, offering superior performance compared to alternative materials. According to a recent market analysis by Grand View Research, zirconium beads exhibit excellent hardness and wear resistance, which can enhance the efficiency of grinding and dispersion processes by up to 30% compared to traditional media such as glass or steel. This advantage is mainly attributed to zirconium's durability, which significantly reduces breakage rates and contamination of processed materials, thus improving overall product quality.

Moreover, when comparing zirconium beads to ceramic alternatives, a study published in the Journal of Materials Science reveals that zirconium beads can maintain consistency in size and shape under aggressive processing conditions. This is crucial in industries such as paint, coatings, and inks, where particle size distribution directly affects the final product's attributes. The erosion resistance of zirconium beads allows for longer service life, leading to lower replacement costs and downtime. Consequently, companies opting for high-quality zirconium beads are likely to experience improved productivity and reduced operational costs, making them a compelling choice in the competitive industrial landscape.

Zirconium beads have become a cornerstone in various industrial applications due to their unique properties and superior performance characteristics. To optimize performance, it is essential to understand the specific techniques for utilizing these beads effectively. One key method involves selecting the appropriate bead size and density based on the materials being processed. For instance, smaller beads tend to offer finer milling and mixing results, while larger beads are more efficient for heavier-duty tasks. Adjusting the size of the beads according to the requirements of the application can lead to significant improvements in efficiency and throughput.

Zirconium beads have become a cornerstone in various industrial applications due to their unique properties and superior performance characteristics. To optimize performance, it is essential to understand the specific techniques for utilizing these beads effectively. One key method involves selecting the appropriate bead size and density based on the materials being processed. For instance, smaller beads tend to offer finer milling and mixing results, while larger beads are more efficient for heavier-duty tasks. Adjusting the size of the beads according to the requirements of the application can lead to significant improvements in efficiency and throughput.

Another crucial technique is the proper operational parameters during mixing or milling processes. Speed and time are vital factors; optimizing these can enhance the interaction between the zirconium beads and the material, resulting in better dispersal and uniformity. Furthermore, maintaining the correct viscosity of the slurry can prevent bead agglomeration, which is essential for maintaining the efficiency of the process. By fine-tuning these parameters and understanding the specific applications, industries can leverage the full potential of zirconium beads, leading to improved performance and cost-effectiveness in their operations.

The advancements in zirconium bead technologies are poised to significantly enhance industrial applications across various sectors. Recent forecasts indicate that the global market for high-purity yttria-stabilized zirconia beads is expected to see substantial growth between 2025 and 2031, driven by increasing demand for high-performance materials in manufacturing processes. Companies are increasingly turning to these advanced zirconium beads due to their superior toughness and wear resistance, which are essential for maintaining efficiency in grinding and dispersion applications.

Emerging trends in the production of zirconium beads include innovations in purification processes and the introduction of more sophisticated stabilization techniques. These developments are expected to yield beads with even higher durability and chemical resistance. According to industry analyses, the introduction of new manufacturing technologies could improve the performance metrics of zirconium beads, leading to enhanced product lifespan and a reduced total cost of ownership for industrial operators. The continuous evolution of this material reflects the growing imperative for industries to adopt superior solutions that meet elevated performance standards.