Choosing the right Zirconia Ceramic Ball can be challenging. The market is filled with various options, each catering to different needs. According to Dr. Jane Smith, a leading expert in ceramic materials, "Selecting the proper Zirconia Ceramic Ball can significantly impact performance and durability."

These balls are crucial in many industries. Applications range from precision machinery to dental implants. The material's strength and resistance to wear make it a popular choice. However, not all balls are created equal. Their sizes, grades, and coatings can vary widely. It’s essential to reflect on specific requirements before making a decision.

Understanding your needs is key. Are you looking for high precision? Or is cost a primary factor? There isn't a one-size-fits-all solution in the world of Zirconia Ceramic Balls. A thoughtful approach will help you navigate these complexities. Remember, a poorly chosen ball may lead to decreased efficiency or higher maintenance costs.

Zirconia ceramic balls are increasingly popular in various applications. Their high strength and toughness make them suitable for demanding environments. Industries like automotive and aerospace utilize these materials for bearings, valves, and pumps. According to a market report by Research and Markets, the global zirconia ceramics market is expected to grow by over 7% annually, reflecting strong demand.

These ceramic balls can withstand high temperatures and corrosion. In many situations, they outperform traditional materials. However, not all zirconia balls are the same. Variations in composition and manufacturing processes can lead to significant performance differences. The importance of selecting the right type cannot be overstated. Some applications demand ultra-fine tolerances, while others may require greater durability.

A common mistake is overlooking the specific needs of the application. For instance, while some may prioritize hardness, others may need flexibility. Understanding the operating conditions is crucial to making an informed choice. This includes factors like load, speed, and environmental conditions. Therefore, reviewing technical data and consulting with experts can be beneficial. Ultimately, each choice should be reflective of both the desired outcome and potential trade-offs in material performance.

When selecting zirconia ceramic balls, evaluating their key properties is essential. Hardness is one major factor. Zirconia balls are known for their high hardness, which improves their wear resistance. However, not all zirconia is created equal. Some may underperform in specific applications.

Another important property to consider is toughness. Toughness dictates how well the ceramic can withstand shock and stress. A ball that chips easily may not be suitable for high-impact environments. It's worth testing a sample before committing to larger orders.

Tips: Always check the specifications provided. Verify that the material matches your application needs. Consult with professionals if unsure about the properties. Understanding the limitations and strengths will guide you toward better choices. Consider potential failures, like unexpected wear patterns, and plan for them in your product evaluation.

Choosing the right zirconia ceramic ball is essential for various applications. To make an informed decision, consider the specific requirements of your project. The size and weight of the balls are critical factors. They directly influence the performance in different environments. Small variations in size can lead to significant differences in performance.

Another important factor is the hardness of the zirconia ceramic ball. Hardness affects durability and wear resistance. For high-stress applications, opt for harder materials. On the other hand, softer balls may be sufficient for less demanding uses. Keep in mind the balance between cost and quality. Sometimes, it’s tempting to choose cheaper options, but this can result in faster wear and increased maintenance.

Additionally, evaluate the chemical resistance needed for your application. Some environments are more corrosive than others. This can impact the longevity of your ceramic balls. Testing in various conditions is advisable. Engage in discussions with peers or seek feedback on choices. Every application is unique, and what works for one may not work for another. Reflection on these factors can lead to better choices.

When selecting zirconia ceramic balls, it's essential to compare the different types available. Zirconia balls can vary in properties such as hardness and density. Some are engineered for high wear resistance. Others might be designed for specific applications. Finding the right fit depends on your specific needs.

For instance, consider the size and shape of the balls. Different industries require balls of varying dimensions. A slight change can impact performance. Some applications may need high precision while others are more forgiving. Evaluate your project's requirements carefully before making a choice.

Another aspect to ponder is the intended environment. High temperatures can affect performance. Not all zirconia balls are created equal in this respect. It's vital to think about how these materials will hold up under extreme conditions. Reflect on where and how you will use them. The right decision can lead to better efficiency, while the wrong one may result in avoidable failures.

| Type of Zirconia Ceramic Ball | Key Properties | Applications | Cost Range (per unit) |

|---|---|---|---|

| Zirconia Toughened Alumina (ZTA) | High toughness, wear resistance | Industrial machinery, automotive components | $1.50 - $3.00 |

| Full Zirconia | Excellent hardness and corrosion resistance | Dental applications, jewelry | $2.00 - $4.00 |

| Partially Stabilized Zirconia (PSZ) | Good thermal stability, moderate toughness | Thermal barriers, mechanical seals | $1.80 - $3.50 |

| Cubic Zirconia | High refractive index, clarity | Fashion jewelry, decorative items | $0.50 - $2.50 |

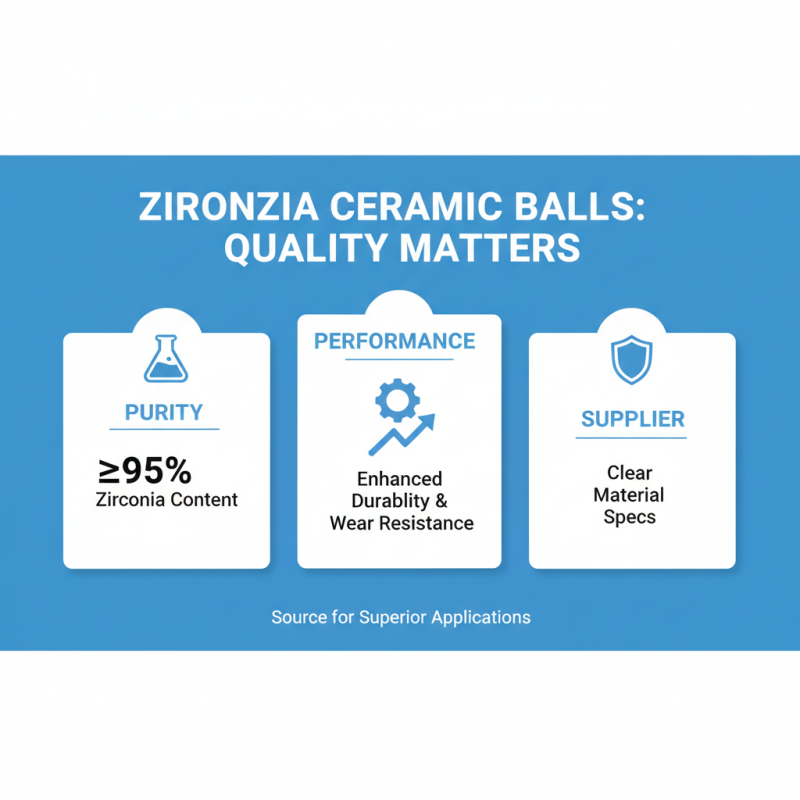

When sourcing zirconia ceramic balls, quality is paramount. According to industry reports, high-purity zirconia can improve performance in various applications. Selecting a supplier who provides clear material specifications is crucial. Look for products with a zirconia content of at least 95%. This ensures durability and resistance to wear and tear.

Purchasing from reliable vendors requires careful evaluation. Check for certifications and testing reports. A reputable supplier often shares their quality assurance practices openly. Many companies adhere to ASTM standards, indicating their commitment to quality. However, not all vendors may meet these standards. Therefore, engaging in discussions with potential suppliers can reveal their commitment and capabilities.

Price is another critical factor. It is tempting to choose the cheapest option, but this may lead to compromises on quality. Research shows that inferior zirconia balls can result in higher long-term costs due to frequent replacements. Assess total cost of ownership instead. This approach considers initial investment, longevity, and performance. Don't rush your decision-making process; reflect on all factors involved for an informed choice.