When selecting the most suitable Zirconia Oxide Balls for various applications, it is crucial to understand the unique properties and benefits these materials offer. Dr. Emily Tran, a leading expert in advanced ceramics, emphasizes the importance of this selection process: “Choosing the right Zirconia Oxide Balls can significantly enhance performance and longevity in demanding environments.” Her insights underline the need for careful consideration of factors such as hardness, density, and chemical resistance.

Zirconia Oxide Balls are favored in industries ranging from aerospace to medical devices due to their exceptional durability and wear resistance. As manufacturers continue to innovate, understanding the specific requirements of each application becomes paramount. The versatility of Zirconia Oxide Balls allows them to be tailored for various operational conditions, ensuring optimal performance and cost-effectiveness.

In conclusion, making an informed choice regarding Zirconia Oxide Balls not only impacts the efficiency of operation but also the overall success of projects. As industries grow increasingly competitive, taking the time to select the best materials can set a foundation for future advancements and reliability.

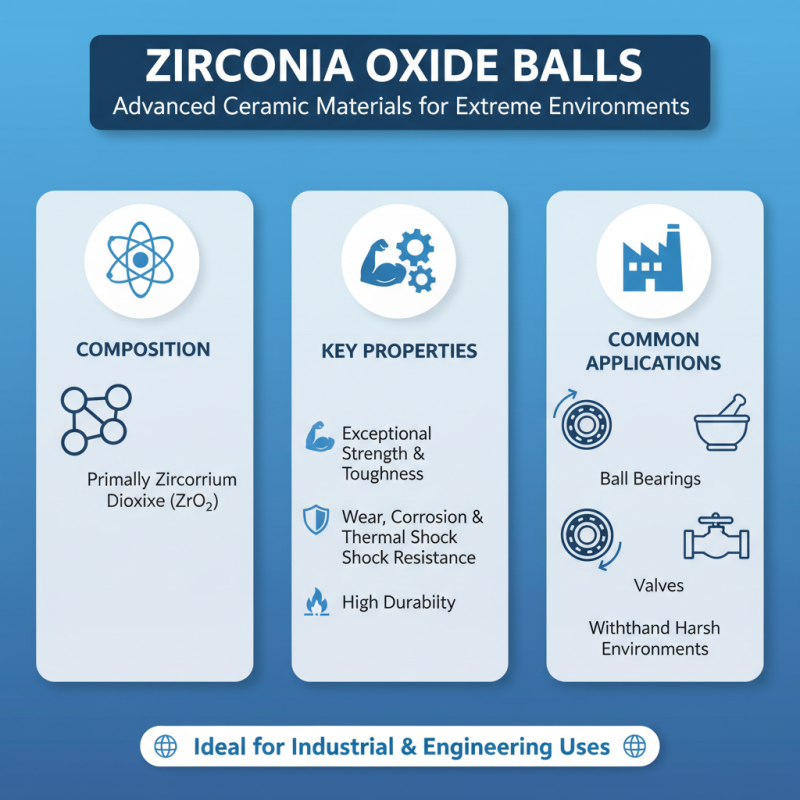

Zirconia oxide balls, also known as zirconium dioxide balls, are advanced ceramic materials known for their exceptional strength and toughness. Composed primarily of zirconium dioxide, these balls exhibit remarkable resistance to wear, corrosion, and thermal shock, making them ideal for various industrial and engineering applications. Their inherent properties allow them to withstand harsh environments, which is why they are commonly used in ball bearings, grinding media, and valves, where durability is paramount.

In addition to mechanical applications, zirconia oxide balls are also utilized in the medical field. Their biocompatibility makes them suitable for dental applications, such as in crowns and bridges, as well as in orthopedic implants where strength and compatibility with body tissues are critical. Furthermore, the electronics industry leverages these materials in capacitors and insulators due to their excellent dielectric properties. Overall, the versatility of zirconia oxide balls ensures they play a vital role in various sectors, enhancing performance while maintaining reliability.

When selecting zirconia oxide balls for various applications, several key properties must be considered to ensure optimal performance. One of the foremost attributes is hardness. Zirconia oxide is known for its impressive hardness, which leads to high abrasion resistance. This quality is particularly significant in applications that involve high wear conditions, such as milling or grinding processes. The ability to withstand wear without degrading means that zirconia balls can provide a longer service life, enhancing operational efficiency.

Another critical property is toughness. Zirconia oxide possesses exceptional fracture toughness, making it suitable for applications that require high impact resistance. This is particularly important in environments subject to sudden load changes or where balls are used in bearings. Additionally, the thermal stability of zirconia oxide is noteworthy; it can maintain structural integrity in high-temperature environments, which is essential for industries such as ceramics and aerospace.

These factors combined make zirconia oxide balls a versatile choice for applications ranging from mechanical engineering to advanced manufacturing settings.

When selecting zirconia oxide balls for various applications, several factors significantly influence their performance. One of the primary considerations is the ball's density, which directly affects its strength and wear resistance. Higher density zirconia balls typically offer improved hardness and reduced abrasiveness, making them ideal for applications that involve high-impact and high-load scenarios. This property is crucial for industries such as milling, grinding, and mixing, where durability is paramount.

Another critical factor is the size and shape of the zirconia balls. The diameter and uniformity of the balls play a vital role in achieving optimal performance. For instance, smaller balls may provide better surface coverage and more efficient mass transfer in mixing applications, while larger balls may be preferred for grinding due to their impact force. Additionally, the surface finish of the balls can influence their interaction with other materials, affecting both the efficiency and the quality of the end product. Thus, considering these factors—density, size, shape, and surface finish—is essential for selecting the right zirconia oxide balls tailored to specific operational needs.

When evaluating quality in selecting zirconia oxide balls, it’s essential to consider several critical factors that determine their performance and suitability for specific applications. The first key metric is the material composition, which significantly influences hardness, wear resistance, and chemical stability. High-quality zirconia typically contains a minimum of 95% zirconium oxide, ensuring enhanced durability and resistance to fracture. Industry reports suggest that zirconia oxide balls with enhanced toughness, such as those produced with Yttria-stabilized zirconia, exhibit superior performance in demanding applications, reducing failure rates in high-stress environments.

Another crucial factor in assessing the quality of zirconia oxide balls is their manufacturing process. Advanced production techniques, including isostatic pressing and sintering, can drastically improve the consistency and homogeneity of the beads. Quality assurance standards such as ISO 9001 indicate that manufacturers adhere to stringent controls, which is a strong signal of reliability. According to a study published by the Journal of Materials Processing Technology, variations in particle size and surface finish are significant contributors to performance outcomes, impacting both the efficiency of grinding operations and the wear rate of the balls over time. Families of zirconia balls evaluated under these parameters consistently yield better results, demonstrating the importance of rigorous evaluation in the selection process.

This bar chart illustrates key quality metrics for zirconia oxide balls, including density, hardness, flexural strength, and fracture toughness. Understanding these metrics can help in selecting the best zirconia oxide balls for various applications.

When selecting zirconia oxide balls for your applications, it is essential to evaluate the various manufacturers in the market to find the right fit. Zirconia oxide, known for its exceptional durability and high wear resistance, is widely used in industries such as ceramics, electronics, and medicine. According to a market research report by Research and Markets, the global zirconia ceramics market is projected to grow at a CAGR of over 6% between 2021 and 2026, highlighting the increasing demand for high-performance materials.

In comparing different manufacturers, it's crucial to assess factors such as the purity of zirconia used, production techniques, and available sizes. High-purity zirconia, typically above 99.9%, exhibits superior mechanical properties, which can impact performance significantly. Additionally, the manufacturing process—such as whether it includes sintering versus non-sintered methods—can influence important characteristics like hardness and density. For instance, a technical study published in the Journal of Materials Science revealed that sintered zirconia balls demonstrated a significant increase in tensile strength compared to non-sintered alternatives, emphasizing the importance of this aspect when choosing your supplier.

Furthermore, reviewing the manufacturer's testing and quality assurance processes is vital for ensuring that the balls meet relevant industry standards, like ISO 9001. Firms that invest in robust quality controls usually yield products with consistent performance, which is critical in applications requiring precision and reliability. Staying informed about the latest advancements in zirconia technology and engaging with manufacturers who prioritize innovation can also provide a competitive advantage, as highlighted in a recent industry analysis by MarketWatch.

| Manufacturer | Ball Diameter (mm) | Density (g/cm³) | Hardness (HV) | Price per Kg ($) | Applications |

|---|---|---|---|---|---|

| Manufacturer A | 0.5 | 6.05 | 1300 | 50 | Grinding Media, Catalyst Support |

| Manufacturer B | 1.0 | 6.10 | 1400 | 55 | Ceramic Engineering, Abrasives |

| Manufacturer C | 2.0 | 6.08 | 1350 | 60 | Medical Devices, Aerospace Components |

| Manufacturer D | 3.0 | 6.12 | 1450 | 65 | Inkjet Print Heads, Coatings |