Zirconium Oxide Beads are gaining popularity in various industrial applications. These beads stand out due to their unique properties. They are hard, durable, and resistant to wear. This makes them ideal for grinding and milling tasks. Their outstanding performance reduces downtime and increases productivity.

Industries often face challenges when selecting materials. Cost, efficiency, and effectiveness are key concerns. Zirconium Oxide Beads offer a great balance among these factors. They do not chip easily, ensuring smooth operation. However, some users may find the initial investment higher compared to alternatives. It is crucial to weigh the benefits against the costs.

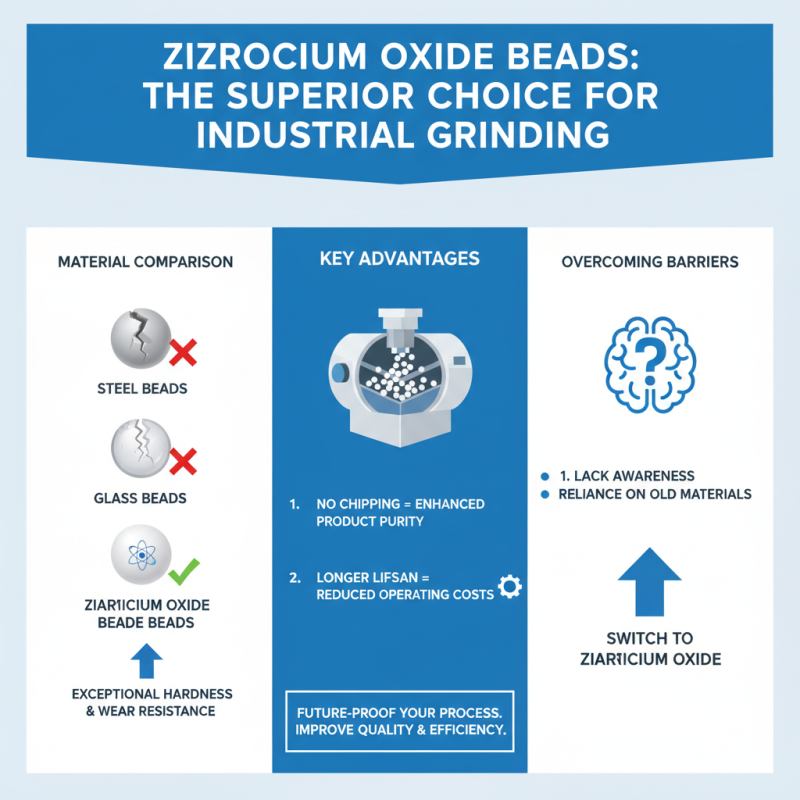

Choosing the right media can improve product quality significantly. Zirconium Oxide Beads help achieve finer particle sizes. This can enhance the effectiveness of final products. Still, not everyone is aware of these benefits. Some industries may overlook them due to past experiences or misconceptions. It’s essential to reconsider and explore the true potential of Zirconium Oxide Beads.

Zirconium oxide beads are becoming popular in various industries. These beads are known for their durability and resistance to wear. This makes them ideal for grinding and dispersion applications. Unlike other materials, zirconium oxide exhibits exceptional toughness. They maintain their shape even under extreme conditions.

Using zirconium oxide beads enhances efficiency. They produce finer particle sizes in a shorter time. This not only saves time but also energy. Industries focused on precision greatly benefit from these beads. They help achieve uniformity in products. However, it is essential to consider cost implications. While zirconium oxide beads can be more expensive upfront, their longevity can lead to savings.

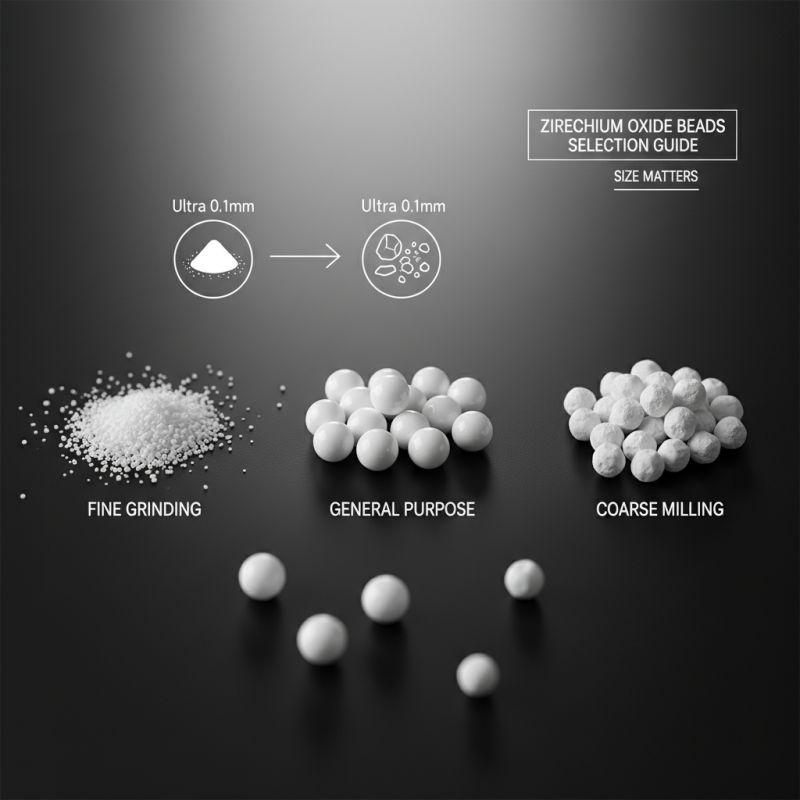

Tips: Choose the right size of beads for your application. Smaller beads work better for finer milling. You also need to ensure proper maintenance of the equipment. Be sure to monitor wear and tear regularly. This way, you can avoid costly replacements. Zirconium oxide beads may seem perfect, but they are not without challenges. Regular evaluation is vital to ensure optimal performance.

Zirconium oxide beads have gained attention in various industrial applications. They are known for their durability and versatility. These beads can withstand high temperatures and aggressive environments. Their wear resistance is impressive. This makes them ideal for grinding and milling processes.

The chemical stability of zirconium oxide beads is significant. They resist corrosion and do not react with many solvents. This property allows for safe use in different industries. Additionally, their density contributes to effective energy transfer during processes. However, it’s worth noting that not all applications utilize these beads effectively. Sometimes, particle distribution can be uneven, leading to inconsistent results.

Furthermore, zirconium oxide beads offer excellent resistance to chipping. This advantage enhances their lifespan in mechanical applications. However, users must be cautious. Depending on the process, wear and tear can be variable. It may require regular monitoring and adjustment. This aspect can pose challenges for maintenance teams looking to optimize production. Overall, while zirconium oxide beads have many benefits, thoughtful application is crucial for achieving desired results.

| Property | Description | Benefits |

|---|---|---|

| Durability | High resistance to wear and mechanical stress. | Longer lifespan in industrial applications, reducing replacement costs. |

| Chemical Resistance | Resistant to acids, alkalis, and other corrosive substances. | Maintains integrity in harsh environments, ensuring product quality. |

| High Density | Higher density compared to other bead materials. | Enhanced grinding efficiency and reduced processing time. |

| Non-reactive | Does not react with materials being processed. | Ensures purity of the final product in sensitive applications. |

| Versatility | Suitable for a wide range of applications within different industries. | Flexibility in use enhances production capabilities. |

When it comes to choosing bead materials for industrial applications, zirconium oxide beads stand out. They possess exceptional hardness and wear resistance. Unlike steel or glass beads, they do not chip easily. This feature is crucial for maintaining product quality. However, some industries may overlook their benefits. This could be due to a lack of understanding or past experiences with other materials.

Comparing zirconium oxide with glass beads shows significant differences. Glass beads may be cheaper upfront, but they wear out faster. In high-impact environments, they break and can contaminate products. This can lead to costly mistakes and product recalls. On the other hand, zirconium oxide beads provide longevity and reliability. Their performance consistency is often superior.

On the flip side, there are considerations with zirconium oxide beads. They can be more rigid in certain applications. This rigidity might not be suitable for every process. Users may find this limiting based on their specific needs. It's essential to evaluate performance versus application context. Balancing these factors is crucial for optimal results.

Zirconium oxide beads are increasingly popular in various industries due to their unique properties. They offer high hardness and wear resistance, making them suitable for abrasive applications. Commonly used in ceramic and glass production, these beads enhance material strength and durability. A report by Research and Markets suggests that the zirconia market is expected to reach $1 billion by 2026. This growth highlights the importance of zirconium oxide in industrial settings.

In the field of pharmaceuticals, zirconium oxide beads are crucial. They are used in drug formulation processes, helping to ensure uniformity and precision. According to a recent study, using these beads can reduce the grinding time by up to 30%. This efficiency allows manufacturers to save costs and improve production timelines.

Tips: When selecting beads, consider the specific application. Ensure they meet your material requirements and industry standards. Always assess the environmental impact of your choices. Also, remember that not all zirconium oxide is created equal; variations exist that might affect performance. Understanding these differences is key to making informed decisions.

When selecting zirconium oxide beads, several factors come into play. One important aspect is the size of the beads. Smaller beads can provide finer grinding, while larger ones are more suitable for coarse processes. It's crucial to understand your specific needs. The hardness of the beads is another factor. Zirconium oxide's superior hardness enhances the efficiency of the grinding process. But, not all applications require the hardest option. Sometimes, a balance of hardness and cost is necessary.

The density of zirconium oxide beads impacts their performance. Higher density beads might be more effective in specific tasks, but they come with a higher price tag. Assessing the type of material you are working with is essential. Some materials may be best paired with lighter beads. It’s vital to consider the environment in which these beads will be used. Abrasive materials may wear them down quickly, leading to constant replacements. Reflecting on your operational conditions can help optimize your choice.

Lastly, think about the lifespan of the beads. Investing in higher quality zirconium oxide may save costs in the long run. However, it's important to avoid chasing perfection. Sometimes, the best solution may be to accept a compromise between performance and budget. A careful analysis of your requirements will aid in making an informed choice.