Choosing the right Zirconia Ceramic Precision Ball is essential for achieving optimal performance in various applications. According to a report by the Ceramic Ball Industry Association, the demand for ceramic balls is expected to grow by 15% annually. This trend highlights the increasing reliance on precision materials in technology and manufacturing.

Dr. Emily Chen, a renowned expert in ceramic materials, emphasizes the significance of these balls, stating, “Zirconia Ceramic Precision Balls offer unmatched durability and precision.” Such properties make them ideal for use in bearings, valves, and many other precision-engineered devices. However, selecting the right type involves many factors, such as size, density, and specific application requirements.

It’s important to note that not every Zirconia Ceramic Precision Ball meets the same standards. The material quality and manufacturing process can greatly influence performance. This necessitates careful consideration and a bit of trial and error. As industries evolve, the need for expert guidance remains crucial in making informed decisions.

Zirconia ceramic precision balls are gaining recognition in various industries. Their durability and resistance to wear make them a popular choice. These balls are commonly used in applications such as bearings, valves, and even in high-temperature environments.

Their unique properties offer several advantages. Zirconia ceramic is lightweight yet incredibly strong. This material provides excellent corrosion resistance as well. However, not all applications require the same specifications. It's essential to consider factors like size, density, and surface finish before making a decision.

Despite their numerous benefits, some applications may find zirconia balls less suitable. For example, in high-impact situations, they can chip or crack. It's important to evaluate the specific requirements of your projects. Identifying the right fit involves a bit of trial and error, which can lead to unforeseen challenges.

When selecting zirconia ceramic precision balls, several key factors come into play. The size and diameter needed for your application are crucial. Ensure you measure accurately. A wrong size can lead to inefficiency.

Material properties are another consideration. Zirconia is known for its hardness and wear resistance. It also has low thermal conductivity. However, not all zirconia is the same. Some may have impurities that impact performance. Always ask for detailed specifications.

Tips: Check for certifications that ensure quality. This can prevent potential issues in the future. Consider the operating conditions as well. High-stress environments may require different properties.

In addition, think about the cost-effectiveness. While high-quality zirconia can be more expensive, it often leads to lower maintenance costs. This trade-off can be beneficial in the long run. Small savings upfront might not be worth it. Always reflect on the impact of your choice.

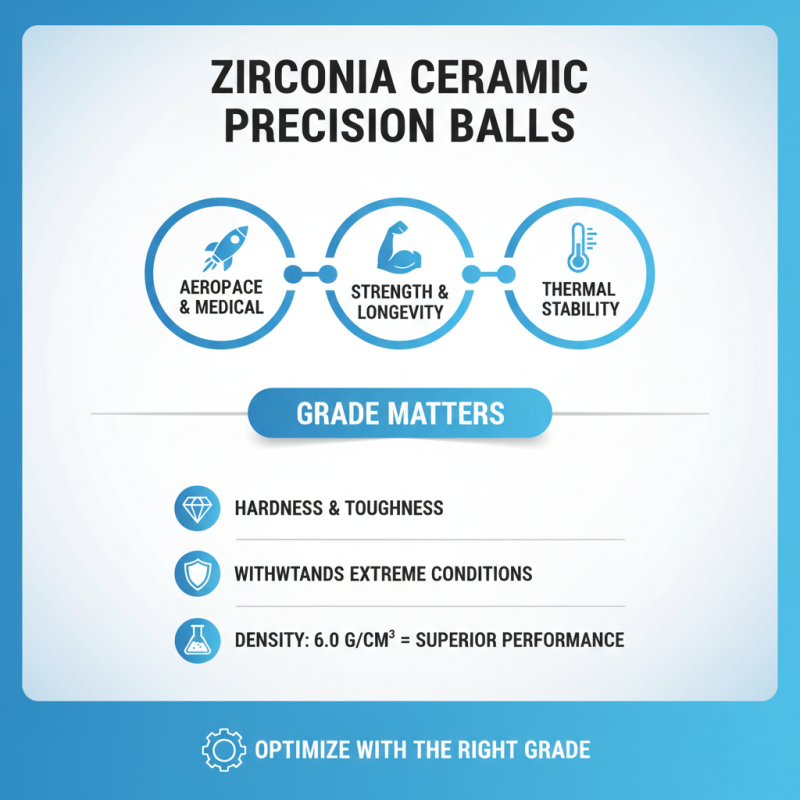

Zirconia ceramic precision balls are essential in various industries, from aerospace to medical devices. Choosing the right grade can significantly impact performance and longevity. Different grades indicate varying levels of toughness, hardness, and thermal stability. For instance, Zirconia balls with a density of 6.0 g/cm³ are reported to have superior strength and withstand extreme conditions.

Quality standards influence their overall use. Most industry reports indicate that higher-quality Zirconia balls tend to have fewer defects. For example, balls with a low porosity (below 0.5%) show improved durability and resistance to cracking. This can lead to annual cost savings of about 30% for manufacturers due to reduced wear and tear on machinery.

However, not all applications require the highest grade. In some cases, mid-range Zirconia balls may suffice for low-stress environments. Choosing a lower grade can be tempting, but it may cause premature failure in critical settings. It's essential to assess the specific demands of your application before making a selection. An improper choice can result in increased downtime and expensive repairs.

Zirconia ceramic balls are increasingly popular in various industries due to their unique properties. These balls offer exceptional hardness, low friction, and excellent wear resistance. According to a recent industry report, the global market for zirconia ceramic products is projected to reach $30 billion by 2027, driven by their applications in sectors like automotive and aerospace.

In the automotive industry, zirconia ceramic balls are critical in bearings, pumps, and valves. Their high strength allows for reliable performance under extreme conditions. The aerospace sector uses these balls for components that require precision and durability, such as turbine engines. The superior thermal and chemical resistance makes them ideal for harsh environments.

Tip: When selecting zirconia ceramic balls, consider factors like size, shape, and application. Not all balls are created equal. Different industries may have varying specifications.

In electronics, zirconia ceramic balls are used in applications requiring precise movement, such as in robotic systems. Their lightweight nature can enhance performance while reducing energy consumption. However, choosing the wrong type could lead to inefficiencies. Some users overlook the impact of surface finish on ball performance.

Tip: Always test samples before committing to larger orders. This can save cost and time. A small oversight in selection can lead to significant operational issues.

| Industry | Application | Diameter Range (mm) | Hardness (HV) | Temperature Resistance (°C) |

|---|---|---|---|---|

| Aerospace | Ball Bearings | 1 - 10 | 1200 | 600 |

| Medical | Dental Tools | 0.5 - 5 | 1300 | 800 |

| Automotive | Fuel Injection | 3 - 12 | 1100 | 700 |

| Electronics | Insulators | 1 - 8 | 1400 | 900 |

| Industrial | Valves and Seals | 2 - 15 | 1250 | 750 |

Maintaining zirconia ceramic precision balls requires attention and care. These components are known for their durability, but neglect can lead to issues. Regular inspections are crucial. Check for wear, chips, or discoloration. Noticing small changes early helps prevent bigger problems later.

Cleaning is essential to their longevity. Use a soft cloth or a brush with bristles. Avoid harsh chemicals that can damage their surface. Gentle soap and warm water are often enough. Rinse thoroughly and dry completely before storage. This helps in preventing any buildup of dirt or grime.

Storage is another key factor. Keep them in a dry, cool place. Avoid extreme temperatures and humidity. If they’re not stored properly, they can suffer from stress and damage. Remember, even precision balls need a little love. Regular attention pays off significantly.