In the pursuit of optimal performance, the role of the Zirconia Ceramic Precision Ball cannot be overlooked. Renowned expert Dr. Emily Grant states, "The precision and durability of Zirconia Ceramic Balls set a new standard in high-performance applications." This highlights the essential characteristics that make these balls a preferred choice in various industries.

Zirconia Ceramic Precision Balls offer unique advantages due to their exceptional hardness and resistance to wear. Their smooth surface reduces friction, enhancing efficiency in mechanical systems. However, the high manufacturing costs can be a barrier for some companies. This trade-off prompts reflection on whether the benefits justify the investment.

The market is evolving, and the demand for Zirconia Ceramic Precision Balls continues to rise. Industries ranging from aerospace to medical devices rely on these components. Nonetheless, challenges remain, such as the need for consistent quality and reliable suppliers. Continual improvement in production methods is crucial to meet these expectations.

Zirconia ceramics are gaining attention in various industries due to their superior properties. They are known for their exceptional hardness and resistance to wear. This makes them ideal for precision applications, especially in environments that require durability. The ability to withstand high temperatures adds to their versatility.

When considering zirconia ceramic precision balls, it’s essential to understand their composition. Zirconia is a white crystalline oxide of zirconium, often found in systems requiring high strength and low thermal conductivity. These balls exhibit excellent toughness, making them suitable for high-stress applications. However, not every zirconia ceramic is created equal. Variability in manufacturing can affect performance.

Tips: Always check the hardness rating before purchasing. A harder ball may not always be better for your application. Also, evaluate the size tolerance specifications to ensure optimal fit and function.

In practice, these materials can sometimes crack under extreme conditions. Regular testing and quality checks are crucial. Users should reflect on the specific requirements of their projects with zirconia ceramics. Each application might expose unique challenges that need tailored solutions.

Zirconia ceramic precision balls are gaining traction in various industries. Their hardness and wear resistance make them ideal for high-performance applications. In automotive sectors, they are used in bearings and valve trains. These components require reliability under extreme conditions. The lightweight nature of zirconia helps improve energy efficiency.

In the medical field, zirconia balls are critical in surgical instruments. Their biocompatibility ensures safety during procedures. They can withstand sterilization processes without degrading. However, challenges remain. The cost of production can be a hurdle for some manufacturers.

In the electronics industry, zirconia balls are employed in precision devices. They enhance the durability of components like connectors and switches. These applications lead to longer product lifespans. Yet, it's essential to continually evaluate quality control. Small defects can have significant impacts. Collaboration among industries can drive innovation and address these issues.

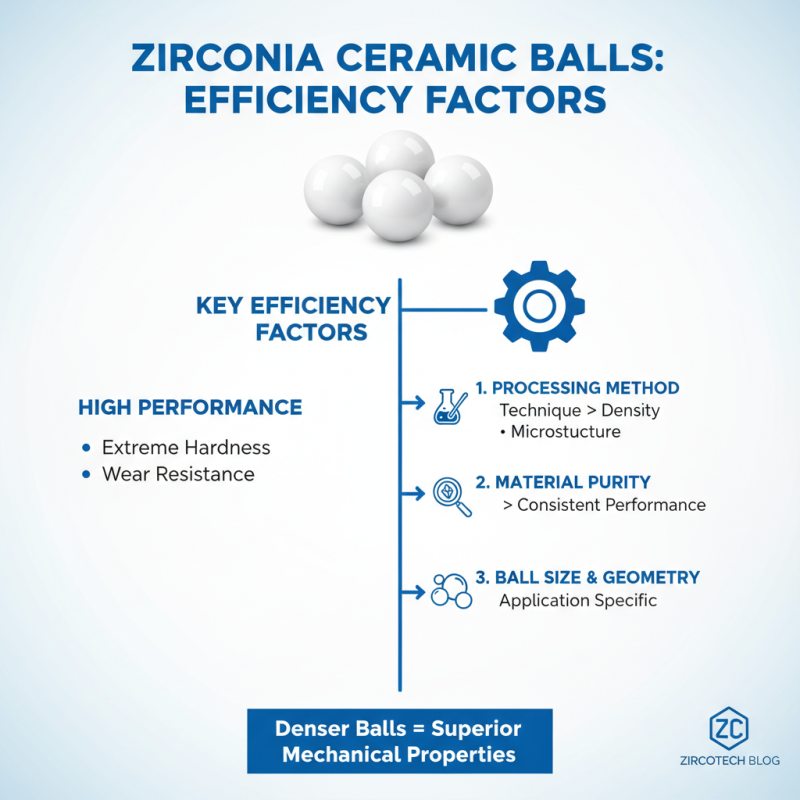

Zirconia ceramic balls are known for their high performance in various applications. However, several factors can influence their efficiency. One key element is the processing method. Different techniques can result in varying densities and microstructures. A denser ball often boasts better mechanical properties.

Another critical factor is thermal treatment. Proper heat treatment can enhance strength. However, excessive heat can lead to internal stresses. These stresses may cause unexpected failures during operation.

The environment in which the balls operate also plays a significant role. Chemical exposure can degrade the material over time. The right coatings can improve corrosion resistance, but they may also affect the ball's motion. Performance is multi-faceted, and attention to detail is essential for optimal results.

Zirconia ceramic balls have gained attention due to their impressive properties. They boast high toughness and wear resistance, making them ideal for various industrial applications. A recent industry report indicates that zirconia balls exhibit a hardness of approximately 1200 HV, significantly outperforming alumina balls, which reach only 1000 HV. This hardness translates to improved durability and longevity.

However, not all applications may favor zirconia over other ceramic materials. For example, while zirconia offers high fracture toughness, it can be more brittle under certain conditions. This contradiction raises questions about its versatility. In low-stress environments, alternatives like alumina could be more cost-effective yet provide sufficient performance.

Further analysis suggests that zirconia’s performance can become less reliable under extreme temperatures. While designed to withstand high thermal resistance, some reports indicate that prolonged exposure beyond 600°C may compromise its integrity. This potential weakness leaves room for reflection regarding the suitability of zirconia in specific applications. The choice between zirconia and other materials must consider these factors carefully.

| Material Type | Density (g/cm3) | Hardness (HV) | Fracture Toughness (MPa·m1/2) | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|---|---|---|

| Zirconia Ceramic | 6.05 | 1200 | 10 | 2.4 | Medical, Aerospace |

| Alumina Ceramic | 3.95 | 1600 | 3.5 | 25 | Electrical Insulators |

| Silicon Nitride | 3.18 | 1900 | 5.6 | 30 | Aerospace, Automotive |

The future of zirconia ceramic ball technology is fascinating. Innovations are changing how these precision balls perform in various applications. New manufacturing techniques allow for better consistency and reliability. The goal is to enhance performance in industries like automotive and aerospace.

Tips: Choose a supplier that focuses on quality. Always check the specifications before purchase. This can save time and avoid complications.

The trend is moving towards smarter materials. Developments in nanotechnology are promising. Zirconia balls will soon be engineered to withstand extreme conditions. These advancements may lead to longer service life and reduced maintenance.

Tips: Keep an eye on industry reports. They provide valuable insights into emerging trends. Staying informed helps in making better decisions.

While the advances are exciting, challenges remain. Perfecting the production process is an ongoing task. There are still concerns about cost and scalability. Reflecting on these factors is crucial for businesses. Embracing change while being prepared for obstacles is key.