The application of 65 Ceramic Zirconium Silicate Beads is vast and significant in various industries. These beads are known for their exceptional hardness and chemical stability, making them ideal for use in grinding, polishing, and surface finishing. According to a recent report by the International Journal of Industrial Ceramics, the demand for zirconium silicate materials has surged by 30% over the last five years. This increase highlights their importance in the manufacturing sector.

Dr. Emily Chen, a renowned expert in materials science, emphasizes the versatility of these beads: "65 Ceramic Zirconium Silicate Beads can enhance product durability and performance." This statement reflects the growing preference for high-quality materials in production processes. The beads are pivotal in achieving finer surface finishes, essential in industries like ceramics and coatings.

Despite their advantages, challenges exist. Not all applications fully leverage the potential of 65 Ceramic Zirconium Silicate Beads. Some industries have yet to realize their benefits. Additionally, sourcing high-quality beads can be inconsistent. Reflecting on these issues may yield insights for future innovations and improvements in bead applications.

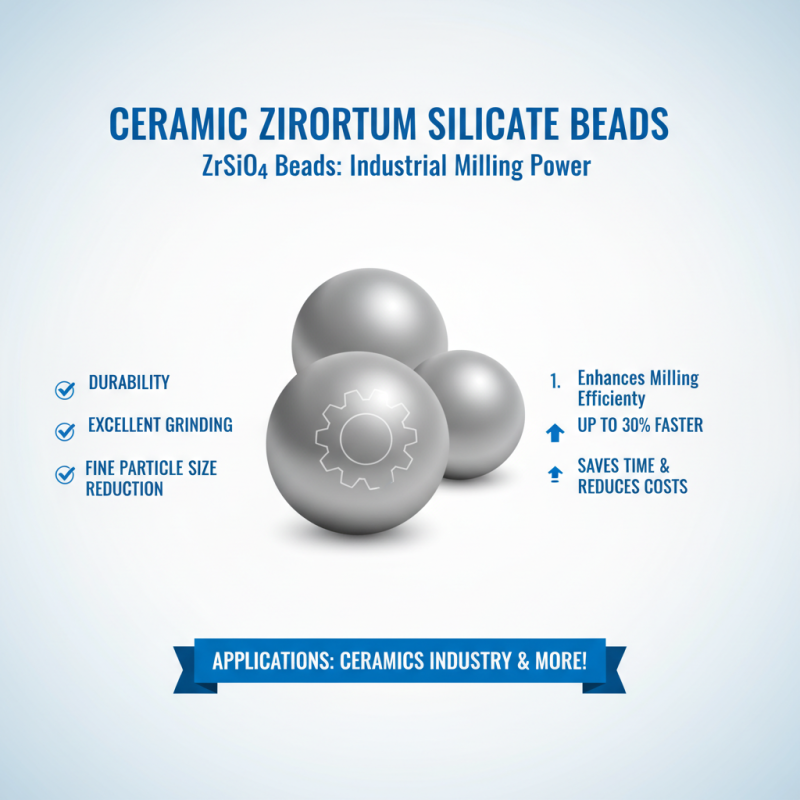

Ceramic zirconium silicate beads, often referred to as ZrSiO4 beads, are versatile materials widely used in various industrial applications. These beads are prized for their durability and excellent grinding capabilities. In the ceramics industry, they play a critical role in achieving fine particle size reduction. Recent studies show that using these beads can enhance the efficiency of milling processes by up to 30%. This significant increase helps manufacturers save time and reduce costs.

In the paint and coating sectors, zirconium silicate beads improve the quality of the end products. They ensure a smooth finish by effectively dispersing pigments and additives. When compared to traditional media, these beads can reduce the need for additional stabilizers by 20%. This finding highlights the potential of zirconium silicate in promoting sustainability by minimizing chemical usage.

However, challenges remain. While these beads are robust, they can be abrasive. This characteristic might lead to wear in some grinding equipment. Manufacturers face a delicate balance between optimal performance and equipment maintenance. Ongoing research emphasizes the need for better formulations to address these issues effectively. Ultimately, the industry must adapt continually to fully leverage the advantages of ceramic zirconium silicate beads.

Ceramic zirconium silicate beads play a vital role in the paint and coating industry. These beads are known for their durability and excellent grinding properties. They are often used in manufacturing high-quality paints, inks, and coatings. According to a recent industry report, the global demand for high-performance coatings is expected to grow by 5% annually. This growth directly impacts the use of ceramic zirconium silicate beads.

Paint formulations benefit from these beads due to their ability to enhance grinding efficiency. They create a smoother finish and improve color consistency. Companies often rely on these beads for high-durability applications, such as automotive paints. Interestingly, some manufacturers report a need to continuously evaluate bead performance to maintain product standards.

Tips: When selecting ceramic beads, consider particle size and density. Different applications require specific properties for optimal performance. Monitor the grinding process regularly to ensure the desired outcomes are met. Finding the right balance may take time, but it’s essential for quality control.

Ceramic zirconium silicate beads play a critical role in producing high-performance polymers. These beads are known for their unique properties. They offer excellent mechanical strength and thermal stability. This makes them perfect for various applications, including coatings and composites.

In the manufacturing process, these beads provide significant benefits. They enhance the dispersion of additives and fillers. This can improve the overall durability of the polymers. However, achieving the desired properties can be tricky. It requires careful control over the bead size and distribution.

Tips: Choose the bead size wisely. Smaller beads can increase surface area but may complicate production. Always conduct thorough testing. This will ensure the final product meets performance expectations. Be ready to adapt your formulation. Sometimes, seemingly small changes in bead concentration can yield big results in performance.

Ceramic zirconium silicate beads play a vital role in ceramic and glass manufacturing. These beads are known for their exceptional hardness and wear resistance. They are commonly used in processes like grinding and milling. With their precise size, they enhance the efficiency of material processing.

In ceramic applications, these beads help in achieving a uniform particle size. This aspect is crucial for ensuring the final product has the desired properties. For glass manufacturing, zirconium silicate beads act as a medium for refining the mixture. This process leads to a smoother finish and improved clarity.

Tip: When working with these beads, choose the right size for your specific application. Smaller beads can provide finer results, while larger ones are more effective for bulk processing. Also, always consider the wear rate of your equipment. Adjusting operational parameters may lead to better efficiency. Don't overlook the importance of regular maintenance to prolong bead life and maintain productivity.

Ceramic zirconium silicate beads are gaining popularity in several fields due to their unique properties. These beads are highly durable and resistant to wear. They also have excellent chemical stability, making them perfect for various applications. In technology, they are used in coatings and surface treatments, enhancing the durability of products.

In research, these beads serve as effective dispersing agents. Their small size allows for better mixing, leading to improved material properties. They can also withstand high temperatures, making them ideal for use in challenging conditions. Their versatility is notable, yet not every application may yield the expected results. It's important to evaluate their suitability for specific tasks.

Tips: When using ceramic zirconium silicate beads, consider their size carefully. Different sizes can lead to varied performance. Always test them in small batches first. This helps ensure you understand their effects on your materials. Regularly assess the results to optimize your processes. Experimenting can lead to discoveries, but it requires a willingness to adapt and learn.